Home » All Products » ENGINEERED STONE

ENGINEERED STONE

Engineered stone is a composite material used as an alternative to solid stone in the making of kitchen countertops. This type of constructed stone material is different from terrazzo because engineered stone is produced on-sight instead of in slabs by a manufacturer. The advantage to using engineered stone is that one is able to take advantage of the durability and appeal of natural stone but at a fraction of the cost because it is not a single shaped and polished piece. The finished product is a combination of crushed stone and polymer resin that sets to harden and permanently form the finished surface. Engineered stone has all the properties of solid stone such as fire resistance and strength but it is less dense and therefore lighter.

Some have confused engineered stone with geopolymers and cast stone, but the differences between these three manufactured stone-like products is related to their base materials and their functions. All three processes involve a crushed stone and bonding agent, but engineered stone is the only term applicable when referencing the material used in the construction of kitchen countertops. There are just as many varieties of engineered stone as there are natural stones.

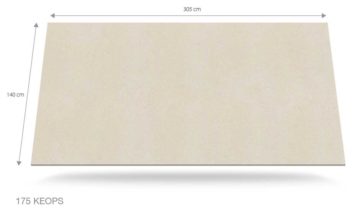

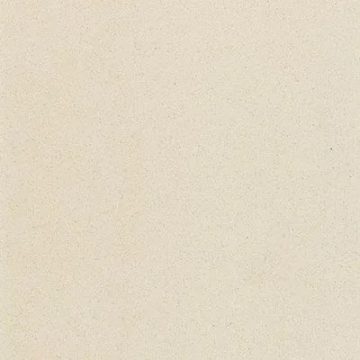

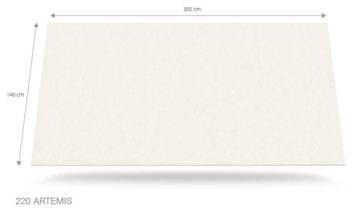

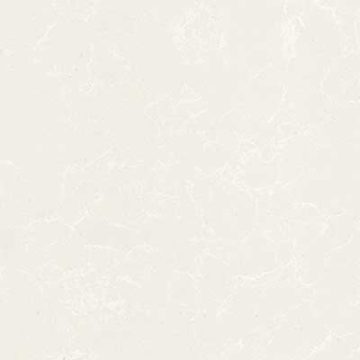

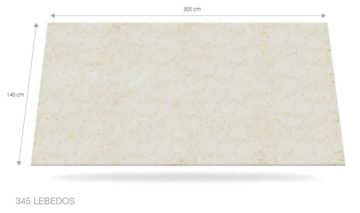

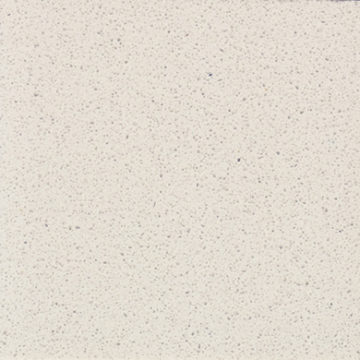

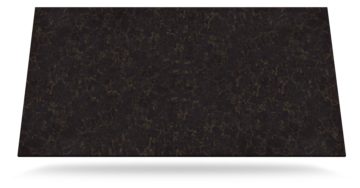

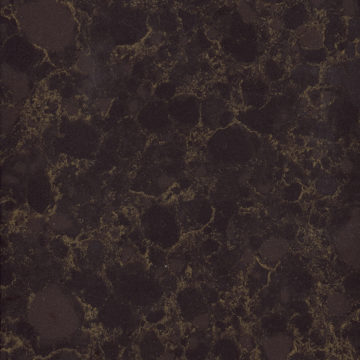

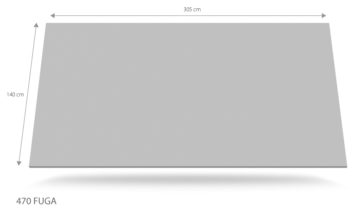

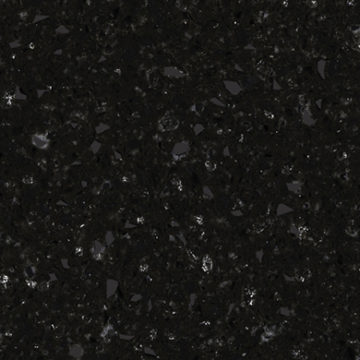

Engineered quartz stone (also known as reconstituted or re-composed stone) is

manufactured from a mix of quartz aggregate chips, a resin binder (typically an

unsaturated polyester), pigments and additives. Engineered stone slabs and counter

tops are available in a wide range of colors, patterns, and even textures. Its texture can

be fine or coarse, depending on how it is processed, and can be combined with glass

and other reflective materials for a sparkling finish. They are increasingly popular in

high-end applications combining the benefits of granite’s durability and non-porous

nature of quartz.